Streamlining MEP Systems Design with MEP BIM Modeling

Table of Contents

Introduction

In today’s construction landscape, the demand for smarter, more efficient, and integrated building systems has never been higher. As buildings become more complex, so too do the systems that keep them functional – the design and coordination of mechanical, electrical, and plumbing (MEP) systems are critical to the functionality, safety, and efficiency of modern buildings.

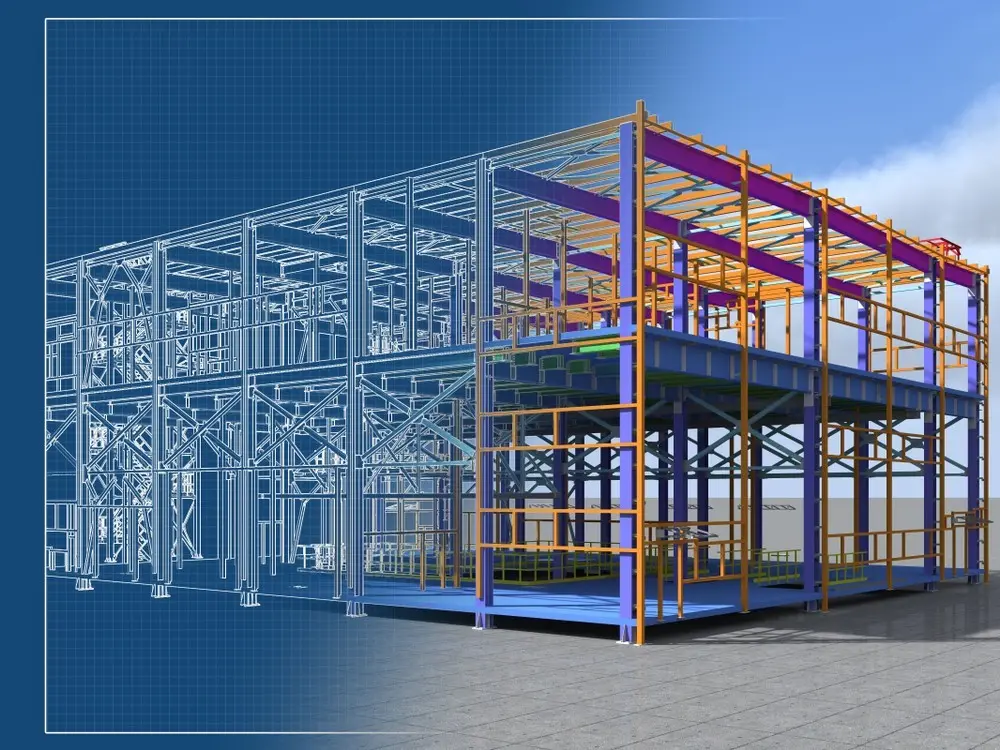

Traditional design methods often involve fragmented workflows, manual coordination, and a high risk of clashes between systems. These challenges can lead to costly delays, rework, and compromised project outcomes. This is where MEP Building Information Modeling steps in, a transformative approach that digitizes and integrates MEP design processes.

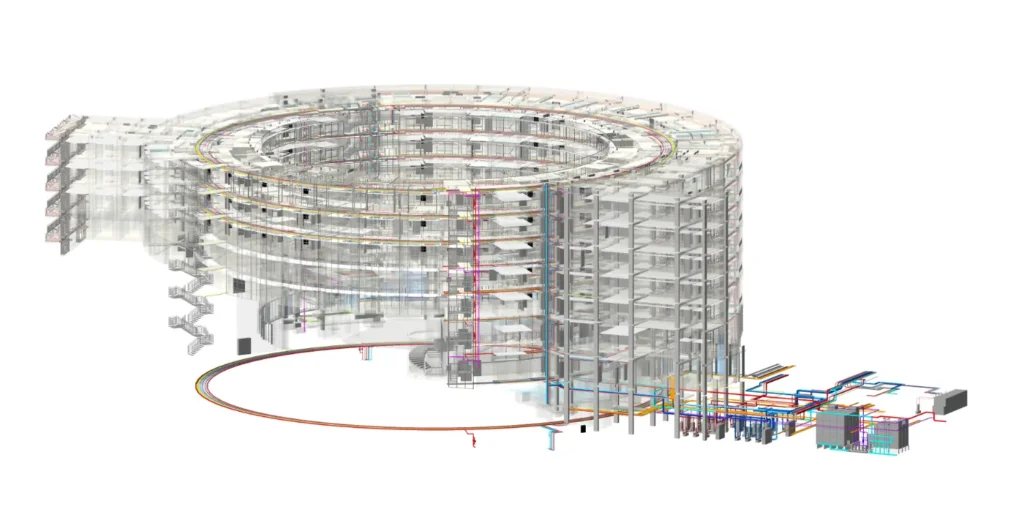

By leveraging 3D modeling, real-time collaboration, and data-driven insights, MEP BIM ensures seamless integration of mechanical, electrical, and plumbing systems. MEP BIM allows architects, engineers, and contractors to collaboratively design, visualize, and coordinate all MEP systems in a virtual environment before beginning any physical work. This article explores how MEP BIM streamlines design, its benefits in integration, and why it is fast becoming an industry standard.

What is MEP BIM Modeling?

MEP BIM modeling involves creating intelligent, data-rich 3D models that represent the physical and functional characteristics of mechanical, electrical, and plumbing systems. Unlike traditional 2D drawings, BIM integrates all aspects of the building into a centralized model – critical data such as dimensions, material specifications, energy performance metrics, and maintenance requirements.

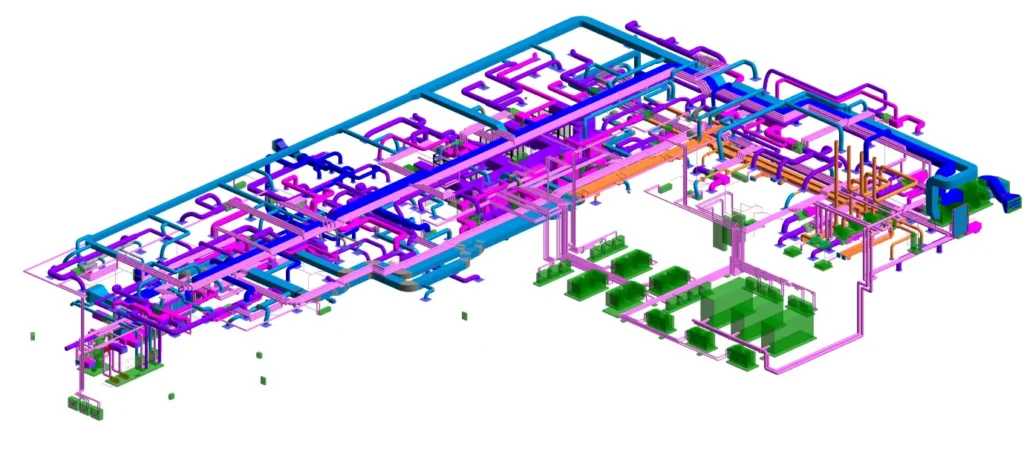

MEP BIM allows various disciplines to work together on the same platform. These models serve as a centralized digital platform where multidisciplinary teams collaborate to design, analyze, and optimize MEP systems before construction begins. It offers a digital representation of the physical and functional characteristics of MEP systems, including HVAC ducts, electrical conduits, fire protection systems, water supply lines, and more.

By simulating real-world conditions, BIM enables stakeholders to identify and resolve conflicts early, ensuring systems are spatially coordinated and functionally integrated. These intelligent models serve as a single source of truth throughout the project lifecycle, from design and construction to operations and maintenance.

Seamless Coordination across Disciplines

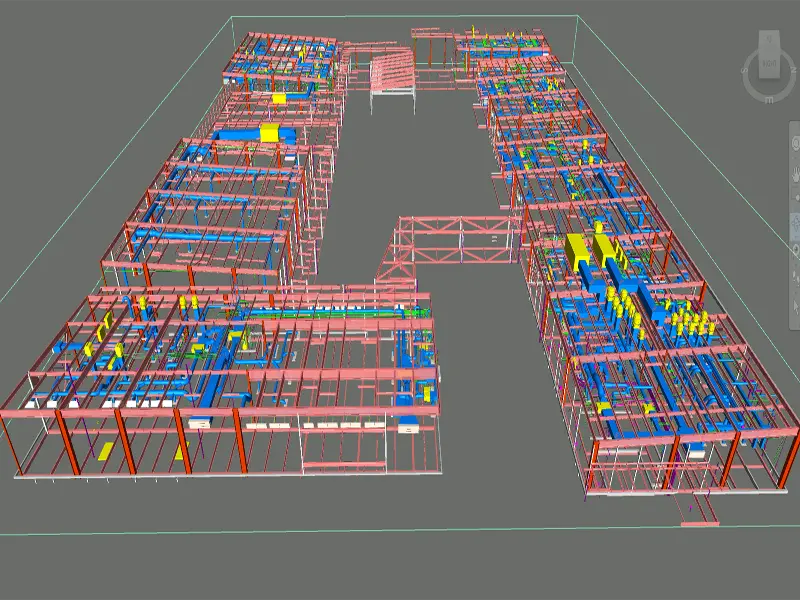

One of the most significant advantages of MEP BIM modeling is its ability to foster seamless coordination among various stakeholders. MEP systems often share tight spaces like ceilings, walls, and floors – without coordination, it is easy for them to clash. Pipes might intersect with ducts, or wiring might interfere with structural beams. MEP BIM breaks down the silos between mechanical, electrical, and plumbing teams by providing a shared digital environment.

MEP BIM software allows architects, structural engineers, designers, and MEP specialists to work concurrently on the same model, reducing miscommunication & duplication of efforts, and identifying & resolving conflicts. This clash detection capability reduces the likelihood of costly field modifications and rework. This ensures that each component fits into the allocated space and operated efficiently without interfering with other systems.

For instance, an HVAC designer can view the routing of electrical conduits in real time and avoid placing ducts in the same path. Similarly, a plumbing engineer can ensure that drainpipes do not obstruct other infrastructure. This synchronized approach results in better project planning, faster approvals, and smoother construction processes.

Enhanced Collaboration and Communication

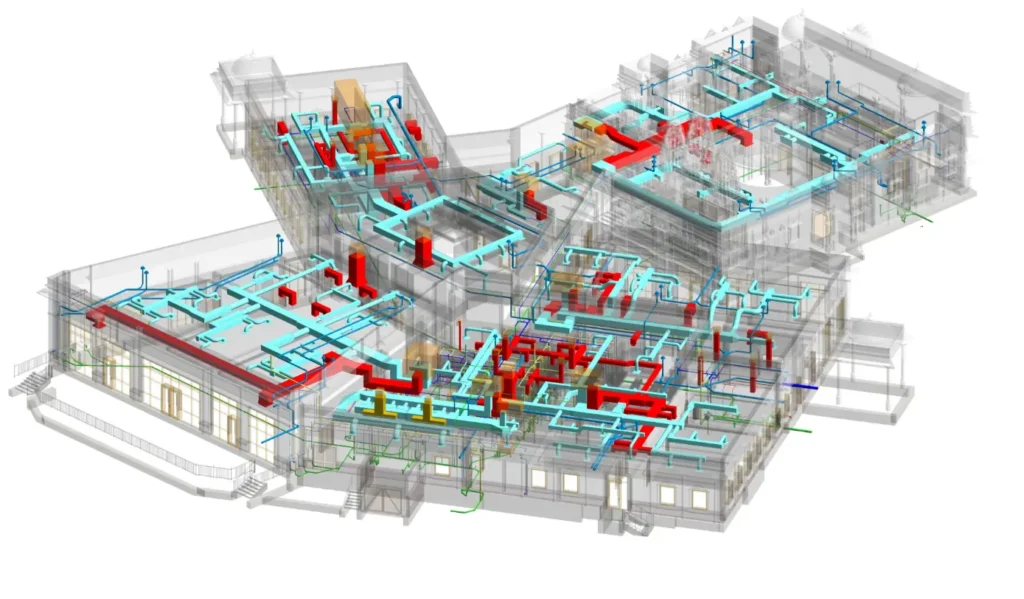

Effective collaboration is critical for delivering successful construction projects. MEP BIM modeling enhances communication between architects, engineers, contractors, and clients by providing a shared digital environment. Through platforms like Autodesk Revit, or Navisworks, stakeholders can visualize the complete MEP layout in 3D, conduct virtual walkthroughs, and provide real-time feedback.

This visual clarity eliminates ambiguities found in traditional 2D plans, allowing all parties to better understand design intent and anticipate challenges. Issues can be flagged and resolved through coordinated review sessions, improving team accountability and minimizing project delays.

Cloud-based BIM platforms, like Trimble SysQue, further streamline collaboration – allowing geographically dispersed teams to contribute updates and access the latest version of the model. This synergy minimizes errors and ensures that all systems align with the building’s architectural and structural framework.

According to a 2021 report by Autodesk, projects using BIM for MEP coordination experienced a 25% reduction in rework costs due to early clash detection and improved collaboration.

Clash Detection and Mitigation

One of the most significant advantages of MEP BIM is its ability to automate clash detection. Software tools like Navisworks analyze the 3D model to identity spatial conflicts between pipes, ducts, conduits, and structural elements. For example, a plumbing pipe intersecting with an electrical conduit or a ventilation duct obstructing a fire sprinkler line can be flagged instantly.

Resolving these clashes during the design phase – rather than on site – saves time, reduces material waste, and prevents budget overruns. Studies show that BIM-driven clash detection can reduce rework costs by up to 30%, making it indispensable for complex projects like hospitals, data centers, or high-rise buildings.

Research from Stanford University’s Center for Integrated Facilities Engineering (CIFE) revealed that BIM-driven clash detection can identify 40% more conflicts during the design phase compared to traditional methods, preventing costly delays.

Improved Accuracy, Reduced Errors, and Design Precision

Traditional design methods rely heavily on manual calculations and fragmented documentation, increasing the risk of human error. MEP BIM modeling automates many of these processes, ensuring greater accuracy and consistency. Intelligent parametric modeling enables changes to one part of the system to automatically update all connected components and documentation.

MEP BIM models are data-rich, enabling engineers to simulate performance under various scenarios. For example, resizing a duct in the model will adjust all related fittings and annotations, reducing discrepancies between drawings and reality. For electrical systems, load calculations, circuit balancing, and energy consumption analyses can be embedded directly into the model. Mechanical engineers can optimize HVAC layouts for airflow efficiency, while plumbing designers can ensure adequate water pressure and drainage slopes.

These simulations improve decision-making and ensure compliance with codes and standards. This reduces reliance on third-party software and helps engineers make data-driven decisions earlier in the design process.

Cost and Time Efficiency

By identifying issues early, MEP BIM modeling accelerates project timelines by reducing costly change orders and on-site conflicts. According to industry reports, clash detection using BIM can reduce rework by up to 40%, leading to substantial savings in labor and materials. Contractors can use the model to generate accurate material take-offs, procurement lists, and installation schedules, reducing delays caused by supply chain bottlenecks.

Prefabrication of MEP components – such as ductwork assemblies or pipe racks – is also streamlined, as BIM provides precise fabrication drawings. On-site labor hours decrease when pre-assembled modules are installed seamlessly, guided by the BIM model. For building owners, this efficiency translates to faster project delivery and earlier return on investment.

Lifecycle Management and Facility Management

MEP BIM modeling goes beyond construction – it plays a crucial role in facility management and operations. Post construction, the BIM model serves as a digital twin for facility management. As-built BIM models contain detailed information about every MEP component – installation dates, manufacturer details, performance data, equipment warranties, replacement & maintenance schedules, and energy usage patterns – extending the lifestyle of MEP systems and reducing operational costs.

Facility managers can use this data to monitor system health, schedule preventive maintenance, and plan future upgrades. This proactive maintenance strategy minimizes downtime and extends the life of building systems. Additionally, BIM models can be integrated with building management systems (BMS) for real-time monitoring and control promoting energy efficiency and sustainability.

Sustainability and Energy Efficiency

Sustainable building design is a priority in modern construction, and MEP systems play a vital role in achieving environmental goals. MEP BIM facilitates sustainable design be enabling energy modeling, simulations, and carbon footprint & performance analysis.

Engineers and designers can evaluate the environmental impact of HVAC systems, lighting layouts, and water usage & recycling strategies to meet green building certification standards – for example, Leadership in Energy and Environmental Design (LEED) and Building Research Establishment Environmental Assessment Method (BREEAM). Ultimately, MEP BIM contributes to creating buildings that are not only functional but also environmentally responsible.

Real World Applications

MEP BIM modeling has proven transformative across industries:

- Healthcare Facilities: Coordinating medical gas pipelines, emergency power systems, and ventilation in hospitals

- Data Centres: Optimizing cooling systems and electrical redundancy for mission-critical infrastructure

- Retail Complexes: Integrating lighting, fire safety, and HVAC systems to enhance occupant comfort

For example, the Shanghai Tower – one of the world’s tallest buildings – relied on BIM to coordinate over 200 MEP subsystems, achieving a 30% reduction in energy consumption.

Finishing Up

As construction projects grow in complexity, the need for integrated, efficient, and intelligent design solutions becomes imperative. MEP BIM modeling is redefining how mechanical, electrical, and plumbing systems are designed coordinated, and managed. MEP BIM is no longer a luxury but a necessity for achieving a seamless integration of complex systems. The UK National BIM Report (2022) highlighted that firms using MEP BIM saw an average 500% ROI over five years, driven by reduced waste, faster approvals, and optimized operational performance.

Building owners benefit from optimized operational performance and cost savings, while engineers and contractors gain a competitive edge through streamlined workflows, enhanced collaboration, and accuracy. In an era where efficiency and sustainability are paramount, MEP BIM modeling stands as a cornerstone of modern MEP design – anticipating challenges, optimizing performance, and delivering smarter buildings for a better future.

Frequently Asked Questions (FAQs)

Is MEP BIM suitable for small-scale projects, or is it only for large scale complexes?

While MEP BIM is highly effective for large, complex projects like hospitals or high-rises, it also benefits smaller projects. Even in compact buildings, BIM ensures systems are optimized for space, energy efficiency, and compliance. The scalability of BIM tools makes them adaptable to projects of all sizes.

Can MEP BIM reduce project costs?

Yes – by resolving clashes during the design phase, MEP BIM minimizes costly on-site rework. It also streamlines material procurement through accurate quantity take-offs and reduces labor costs via prefabrication. Studies indicate BIM can cut project costs by up to 20% by improving efficiency and reducing waste.

How does MEP BIM support sustainable building practices?

MEP BIM integrates energy modeling tools to analyze HVAC efficiency, lighting systems, and water usage. Engineers can iterate designs to reduce energy consumption, carbon emissions, and operational costs. Post-construction, the BIM model acts as a digital twin for monitoring system performance, aiding in long-term sustainability goals like LEED certification.

How does MEP BIM improve on-site construction efficiency?

MEP BIM models enable prefabrication of system components – like ductwork, pipe racks – using precise fabrication drawings. Contractors can install pre-assembles modules on site with minimal rework, reducing labor hours and material waste. The model also serves as a reference for accurate installation, minimizing errors and delays.

Ready to optimize your next project with advanced MEP BIM solutions?

Contact us today to discuss how we can help streamline your building design and construction!

Contact Us

Leave a Reply